Built for Uptime

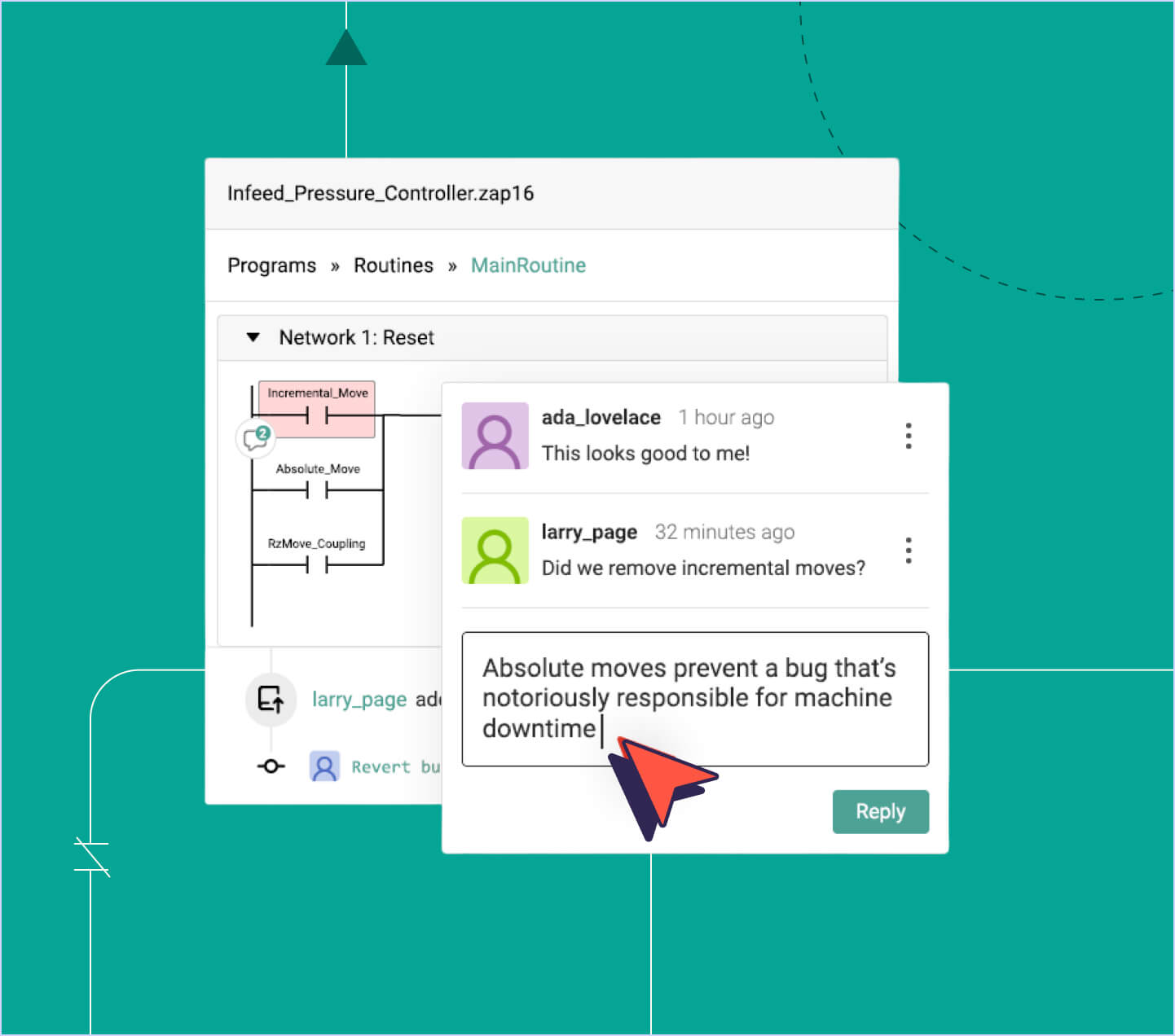

Your code is a critical asset. Treat it like one.

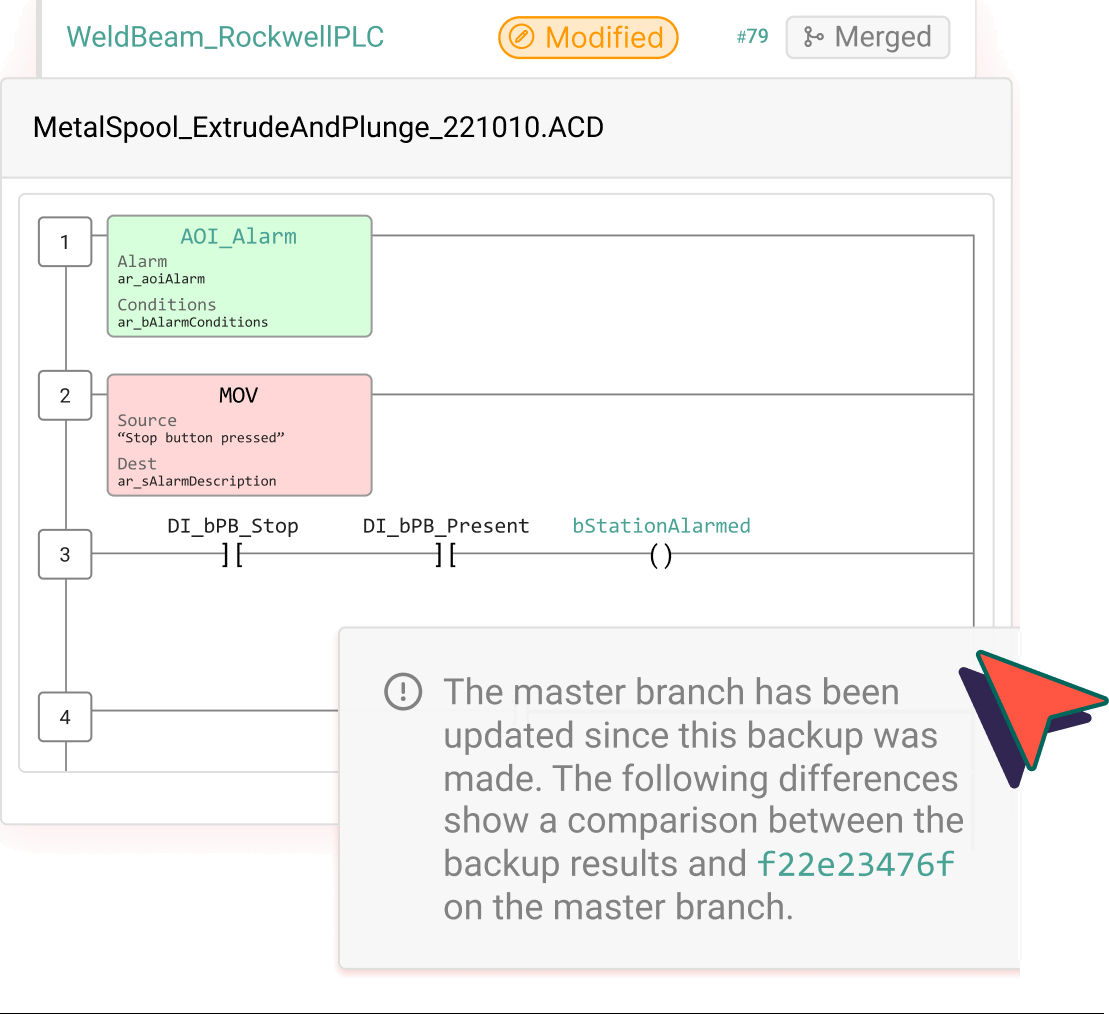

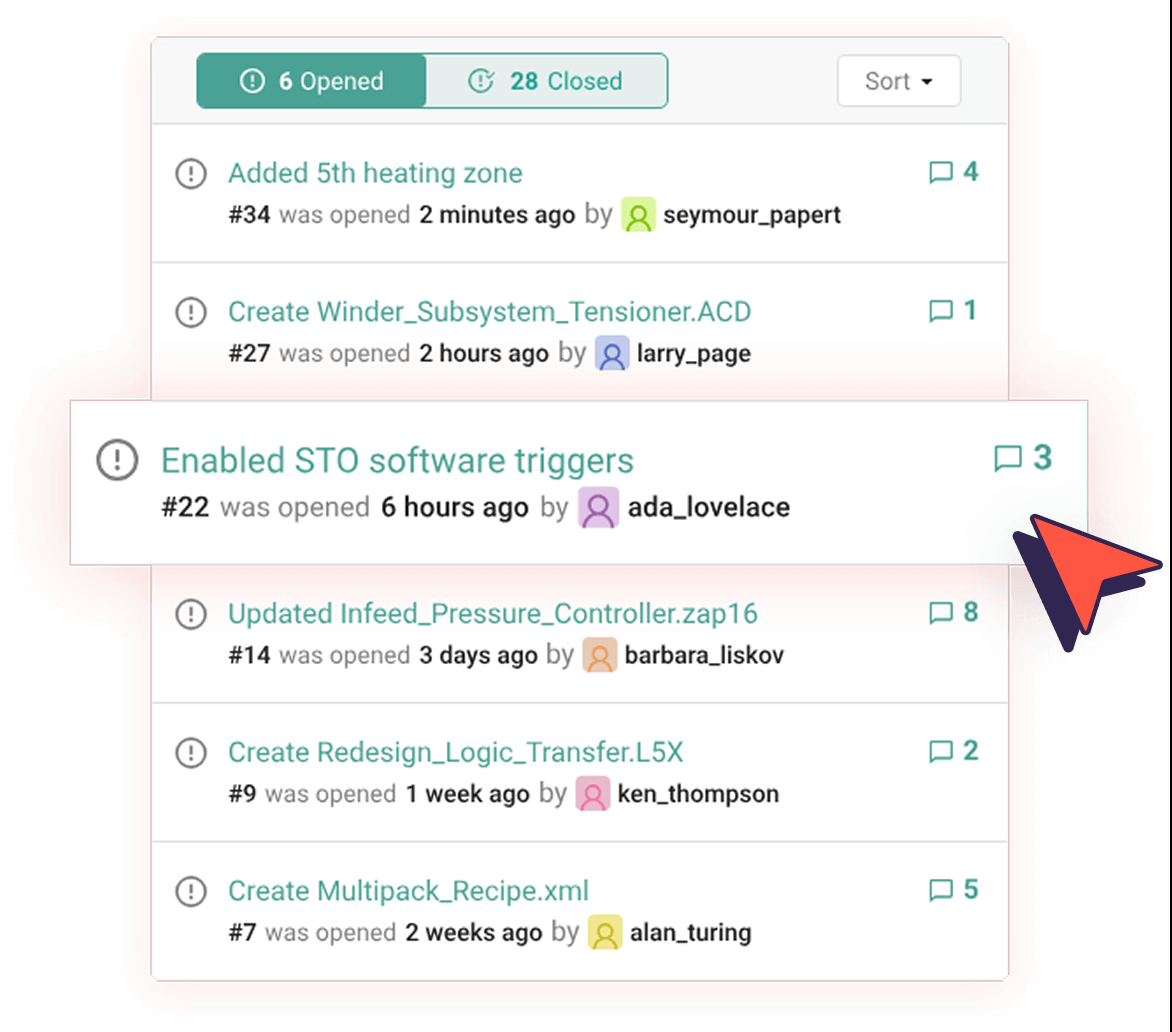

The world’s largest and most innovative companies manage PLC code with Copia. Monitor, approve, back up, audit, and collaborate on industrial code with the Copia Industrial Code Lifecycle Management platform.