Ah, the 1980s. Big hair, neon colors, synth-pop, and the birth of the personal computer. It was a decade of iconic moments and cultural shifts. Allen-Bradley released the PLC-5 family, first to use a 16-bit processor and support multiple programming languages. Things were great!

But let’s face it, not everything from the ’80s has aged well. While we fondly remember hairbands and cassette tapes, some things are better left in the past—like the way many organizations still manage their operational technology (OT), particularly their Programmable Logic Controllers (PLCs).

The Good Ol’ Days (or Were They?)

The PLC, first patented in 1968, revolutionized industrial automation during the 1980s as processors evolved along with CPU designs, making PLCs more efficient and less costly. But in many factories and plants, it feels like we’re stuck in a time warp. We’re still relying on antiquated machines accompanied by outdated processes, like sneakernet (yes, literally walking around with USB drives) to manage and update these critical systems.

Just as Rotary Phones gave way to Smartphones, and VHS Tapes were ousted by Streaming and Blu-ray, it is time Paper-Based PLC Management is replaced by a modern equivalent in Industrial DevOps. Why is this upgrade essential? So that organizations can achieve version control, automation, collaboration, and cybersecurity!

The ’80s Called, They Want Their OT Management Back

Just like those clunky relics, outdated OT management practices are holding your organization back. They create bottlenecks, increase downtime, and expose you to significant cybersecurity risks.

Here are some pain points that scream “the late 1900s” in today’s OT environments:

- Manual Processes & Paperwork: Keeping track of PLC code versions and configurations with spreadsheets and/or endless file folders in Sharepoint. It’s time-consuming, error-prone, and a security nightmare.

- Sneakernet: Still using USB drives to transfer code updates? This is not only inefficient but also introduces the risk of malware and unauthorized changes.

- Siloed Teams: Are your IT and OT teams operating in isolation? This lack of collaboration hinders visibility, slows down troubleshooting, and creates security blind spots.

- Reactive Maintenance: Waiting for equipment to fail before taking action? This leads to unplanned downtime, production losses, and frustrated customers.

Industrial DevOps: The Fast Track to Modernization

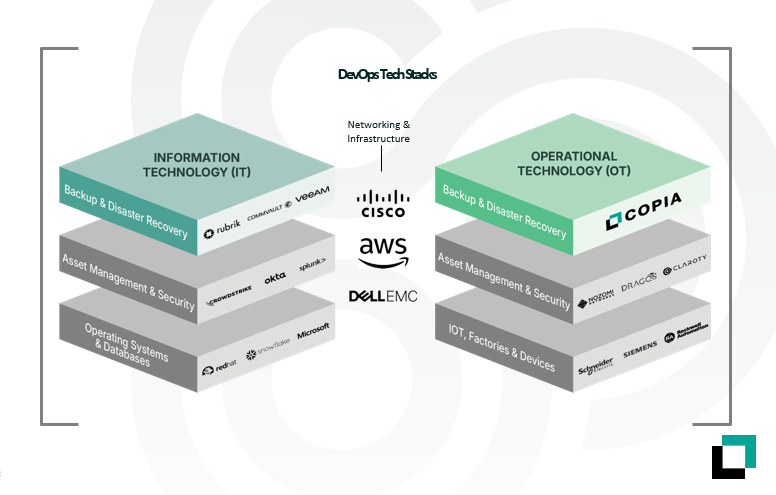

Industrial DevOps is the key to breaking free from the last century and modernizing your OT management. By applying the principles of DevOps – collaboration, automation, and continuous improvement – to the industrial world, you can:

- Reduce Downtime: Implement version control, automated testing, and streamlined deployment processes to minimize errors and ensure smooth updates.

- Enhance Cybersecurity: Gain visibility into your OT environment, track changes and access, and implement security best practices to protect your critical systems.

- Boost Agility & Innovation: Enable faster response to market changes and customer demands with rapid iteration and seamless updates.

- Prepare for Disaster: Automated cloud backup creates alignment with your organizations Business Continuity Plan (BCP) and has you covered for Disaster Recovery (DR).

- Empower Your Workforce: Automate routine tasks, foster collaboration, and provide a platform for knowledge sharing to address the skills gap and improve productivity.

It’s Time to Upgrade: Embrace the Future with Industrial DevOps

Just as we’ve embraced streaming services and smartphones, it’s time to upgrade our approach to OT management. The benefits of Industrial DevOps are clear: improved efficiency, enhanced security, and increased agility.

Don’t let your organization get stuck in nostalgia. Embrace Industrial DevOps and fast-track your modernization efforts. Your PLCs, your growing list of other OT devices, and your bottom line will thank you.

Call to Action:

Ready to break free from the late 1900s and modernize your OT management? Contact Copia Automation today to learn how our Industrial DevOps platform can help you achieve greater efficiency, security, and agility.