The world of manufacturing and distribution is undergoing a seismic shift. Industry 4.0, the Industrial Internet of Things (IIoT), and a wave of digital transformation initiatives are pushing organizations to become more connected, data-driven, and agile. However, many companies are still clinging to outdated operational technology (OT) practices, creating a dangerous status quo that threatens their productivity, security, and long-term viability.

In this blog post, we will explore the top 5 dangers of the status quo in manufacturing and distribution organizations.

1. Crippling Downtime

Unplanned downtime is a nightmare scenario for any manufacturing or distribution organization. According to Copia’s recent State of Industrial DevOps Report, 67% of organizations face downtime costs exceeding $1 million per hour. The reliance on ad-hoc fixes and manual processes often leads to cascading failures and prolonged outages, impacting production schedules, customer satisfaction, and the bottom line.

The status quo, with its lack of version control, automated testing, and streamlined deployment processes, is a recipe for disaster. The slightest error in code deployment can bring an entire production line to a grinding halt, causing ripple effects throughout the value chain of a company. Embracing Industrial DevOps practices, such as those enabled by Copia’s Industrial DevOps platform, can drastically reduce downtime by providing automated backups, version control, and a centralized code repository.

2. Escalating Cybersecurity Risks

The convergence of IT and OT has expanded the attack surface for cybercriminals, making industrial systems increasingly vulnerable to breaches. As per the report, a staggering 47% of unplanned downtime is caused by cybersecurity incidents.

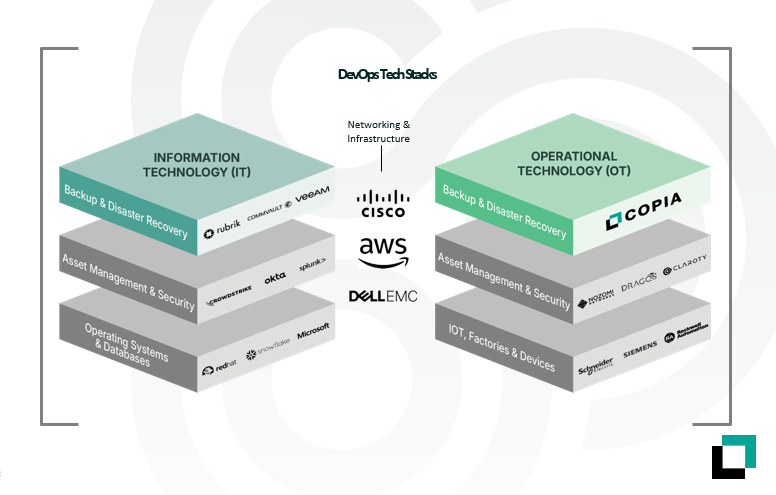

The status quo’s fragmented security approach and lack of real-time visibility into OT environments leave organizations exposed to threats like ransomware and data breaches. Industrial DevOps, with its emphasis on DevSecOps principles, integrates security into every stage of the development and deployment process, ensuring that systems are protected from the ground up.

3. Stifled Innovation & Agility

In today’s fast-paced market, the ability to innovate and adapt quickly is paramount. The status quo, with its long development cycles, manual processes, and siloed teams, hinders innovation and agility. Organizations clinging to outdated practices risk being left behind as competitors embrace digital transformation and respond swiftly to market changes.

Industrial DevOps fosters a culture of continuous improvement and collaboration, enabling organizations to iterate rapidly on product development and deploy updates seamlessly. This agility allows companies to bring new products to market faster, customize offerings to meet specific customer needs, and respond effectively to disruptions in the supply chain.

4. Workforce Challenges & the Skills Gap

The manufacturing and distribution sectors are facing a growing skills gap, as experienced workers retire and new talent struggles to keep up with the rapid pace of technological change. The status quo’s reliance on manual processes and specialized knowledge exacerbates this challenge, making it difficult to onboard new employees and maintain operational efficiency.

Industrial DevOps can alleviate workforce challenges by automating routine tasks and providing a platform that enhances collaboration and knowledge sharing. By streamlining processes and reducing the learning curve, organizations can empower their workforce to focus on higher-value activities and drive innovation.

5. Missed Opportunities for Growth & Efficiency

The status quo represents a missed opportunity for organizations to unlock their full potential. By clinging to outdated practices, companies are leaving significant gains in efficiency, productivity, and profitability on the table.

Industrial DevOps offers a pathway to realize these opportunities by optimizing operations, reducing costs, and enabling data-driven decision-making. The adoption of Industrial DevOps practices allows organizations to break down silos, streamline workflows, and leverage advanced technologies like AI and machine learning to improve efficiency and gain a competitive edge.

Conclusion

The status quo in manufacturing and distribution is no longer sustainable. Organizations that fail to embrace Industrial DevOps risk falling behind in an increasingly competitive and digitally driven landscape. The dangers are clear: crippling downtime, escalating cybersecurity risks, stifled innovation, workforce challenges, and missed opportunities for growth.

By adopting Industrial DevOps principles and solutions, organizations can break free from the status quo and build a secure, agile, and innovative future for their operations. The time to act is now.