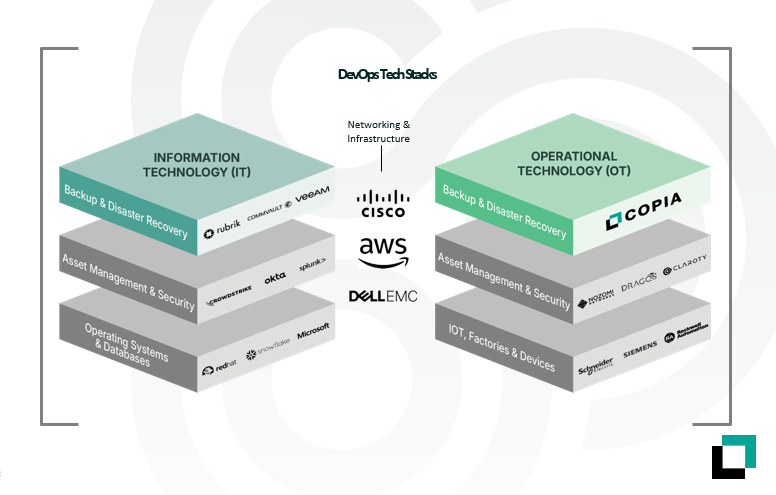

Just as the familiar DevOps has made software development practices more nimble, Industrial DevOps promises similar efficiencies and productivity boosts for automation engineers. The challenge?

Framing Industrial DevOps in a way that helps top management understand its real business value as opposed to seeing it as another costly investment. Read on to learn more.

What is Industrial DevOps?

Compared to traditional automation tools and practices, Industrial DevOps is designed from the ground up for collaboration. Industrial DevOps tools and practices maintain all vendor files and source code in a shared repository, giving engineers end-to-end visibility and control over code changes.

The approach mitigates common bottlenecks of conventional practices such as the need to wait on others for work, limited code review processes, and the need for collaborators to be in the same room, looking at the same screen to co-develop code.

A best-in-class Industrial DevOps platform delivers a Git-based, common source control repository, continuous code and device validation, and active monitoring and alerts to address many of these hurdles. In the best case scenario, the toolset should offer automatic, revertible backup capabilities to get easy access to past configurations, ensuring that any offline devices can quickly become functional again.

In short, Industrial DevOps done right ensures automation code is managed with the same level of rigor and resiliency that is now commonplace in IT.

The features and benefits that resonate so well for automation engineers may not be so apparent to top management. The executive branch is typically less technical with greater concerns about meeting critical business targets such as reducing costs, improving employee productivity, or maximizing uptime.

Making the business case

With that in mind, here’s how to craft a convincing business case for Industrial DevOps in a language top management will understand:

Enhances productivity. In most environments, industrial engineers are stuck having to juggle dozens of bespoke or proprietary vendor tools to maintain control systems and ensure maximum uptime.

This requires learning multiple tools and toggling between applications to get the job done, which is time consuming and confusing. With an Industrial DevOps platform, engineers can leverage one platform to manage and update automation code, allowing them to be far more productive.

Moreover, an Industrial DevOps platform can help attract and retain younger engineering talent as they are likely to prefer working with modern programming tools over legacy systems.

Promotes innovation. Tracking down problems and fixing code can be a painstaking process with conventional automation and control platforms.

The visualization capabilities offered by an Industrial DevOps platform helps engineers quickly pinpoint and fix issues without having to comb through code to figure out what’s wrong. Freed up from laborious, manual processes, engineers get hours back in their day to focus on innovation and more value-added work.

The key is choosing a tool with visualization capabilities that work across multiple vendor platforms, because multiple vendor support means users don’t have to learn and be trained on multiple methods. A cloud-based platform means that review and collaboration can be done from anywhere with or without vendor-specific tools.

Mitigates downtime: With less time spent searching for problems and more time allotted to identifying issues that can be addressed proactively, manufacturers have a better shot at averting costly downtime.

In the event a problem does occur, an Industrial DevOps platform will allow programmers to easily revert back to older instances of code, which ensures better resiliency and lessens the impact of assets going offline for any length of time.

Bolsters security and agility: The threat landscape has only become more active and complex, and industrial assets have become potential targets right alongside IT systems.

The right Industrial DevOps platform serves as another layer in securing the Industrial environment, allowing controls engineers to quickly and effortlessly make changes to adapt to evolving business requirements along with looming cybersecurity threats.

Industrial DevOps is a critical investment in improving productivity and driving efficiency for the whole of the business.

Want to take a deeper dive into Industrial DevOps? Grab your copy of The Exec’s Guide to Managing OT.